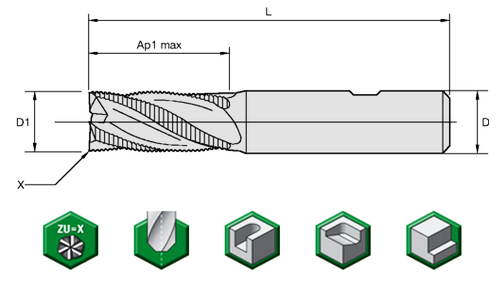

roughing end mill diagram

4 Flute Single Pitch Corner Radius end mill Rea. CNC Milling Tools hot sale good quality use for.

Roughing End Mill Kyocera Unimerco

4F CNC Solid Carbide Roughing end mill cutter C.

. Roughing end mills also known as hog mills are used to quickly remove large amounts of material during heavier operations. Drill A tool for drilling. Roughing end mill This kind of end mill utilizes a wavy tooth form cut on the periphery.

Side milling curved surface milling and drilling are possible only by one. Line of solid carbide end mills and hundreds of standard end mills in a variety of coatings. Made roughing mill designed for accelerated stock removal.

Great for large surface area work roughing end mills have numerous serrations teeth in the flutes to quickly remove large amounts of material leaving a rough finish. Cobalt Roughing End Mills are designed for roughing or hogging large amounts of metal prior to a finish milling operation. Ball end mills also known as ball nose end mills are used for milling contoured surfaces slotting and pocketing.

Multiple teeth come into contact with the workpiece at the same time. Cutting edges are only on a top. This reduces chatter and vibration which could otherwise be larger because of the jagged teeth.

A ball end mill is constructed of a round cutting edge and used in the machining of dies and molds. Every business must consider which end mill best fits the desired application and results in minimum production costs. Figure 11 shows surface temperature variation of the work-rolls in the roughing mill where they are cooled using two water sprays with convection heat transfer coefficient of 30 000 W m 2 K 1 and heat transfer coefficient for the film cooling region is taken as 6000 W m 2 K 1.

Roughing End Mills - Cobalt and High Speed Steel. 18 Roughing End Mill. 2Speedy cutting and consume less power.

Some end mills with fewer flutes are called roughing end mills as the fewer flutes mean. Download scientific diagram RDOC milling strategy 12 from publication. Carbide Square End Mills.

Roughing End Mill. Steel Roughing rolling mill stand is an important part of a work stand roll bearing chock and roller adjustment device is installed on the frame. Milling cutter A rotary cutting tool having many cutting edges on the periphery or an end face of a cylinder and a cone.

Tooling Materials Expensive high quality materials yield more durable tools that. Made of solid carbide these end mills are harder stronger and more wear resistant than high-speed steel and cobalt steel for the longest life and best finish on hard material. A roughing end mill the type with a wavy corncob outer flute cuts into the part at a higher ratio to the rotation.

End mill A multi-functional tool which has cutting edges on the periphery and an end face. Plunge Milling is a type of CAM Toolpath though it can be programmed manually as we will see. Roughing endmills will take a cut the full length of the mill in a pass to cut a slot at a faster rpm and feed than a standard endmill.

The idea is to rough out a pocket profile or 3D surface by plunging either a twist drill an end mill or a special-purpose tool straight down into the material. Originally Posted by ChipSplitter. It is measured from the start of the necked portion to the bottom of the cutting end of the tool.

The roughing end mill has jagged teeth. The overall reach of an end mill or length below shank LBS is a dimension that describes the necked length of reached tools. The cut bits of metal are smaller than usual and therefore easier to clear.

These make the cutting process faster than with a regular end mill. The Mechanism of Position-Mode Side Guide in. Large temperature variations occur at the surface region of the work-roll owing to severe temperature.

Heavy cuts can be achieved because our roughing end mills have a much higher effective feed per tooth than a conventional end mill. Ruff-N-Tuff fine-pitch roughers for cutting high-temperature alloys and Ruff-N-Touch end mills for roughing and finishing in one. Fastcut manufactures Ruff-N-Cutt the original US.

Normally a 20 reduction in effective horsepower is used. LHY HSS roughing end mill 4 flute. Choosing an end mill is no simple task.

The steel roughing rolling mill stands are used to reduce the thickness of the steel while at the same time extending the overall length. The spiral flute end mill compared to a straight flute does a similar function. 06-12-2020 0902 AM 61.

They are sometimes referred to as Corn Cob cutters or Hog Mills - so called after the pig who grinds away or consumes anything in its path. Lets start by taking a look at what plunge milling is. This is illustrated in the.

Corner Rounding End Mills. 1Made of High Speed Steel its durable an important fittings for your device. View Kennametal End Mill Catalog For Application Corner Configuration Diameter More.

Ad Large Selection of End Mills From General Purpose Modular High-Performance End Mills. The idea is to rough out a pocket profile or 3D surface by plunging either a twist drill an endmill or a special-purpose tool straight down into the material. CNC Milling Tools hot sale good quality use for.

These lower the shock load during the cutter rotation both enabling a heavier cutting load. If so maybe plunge milling also called plunge roughing is the answer. View Profile View Forum Posts Titanium Join Date Feb 2014 Location FL Posts 3472 Post Thanks Like Likes Given 11844 Likes Received 4002.

Series Multimaster Milling Tip Style MM ERA Milling Tip Type End Mill Material Carbide Cutting Diameter mm 800 Manufacturers Grade IC08 Depth of Cut mm 500 Number of Flutes 3 Coating Uncoated Milling Tip Full Description Roughing End Mill Corner Radius Decimal Inch 00080 Extension From Holder mm 1000 Thread Size T05 Helix Angle 45. CNC Milling Tools hot sale good quality solid c. Form-relieved edges stay constant and can be.

These wavy teeth form many successive cutting edges producing many small chips resulting in a relatively rough surface finish but the swarf takes the form of short thin sections and is more manageable than a thicker more riboon-like section. The neck relief allows space for chip evacuation and prevents the shank from rubbing in deep-pocket milling applications. Download scientific diagram Dimensions of the roughing mill components and side guide.

You do have to use a mist coolant system to get the chips out of the slot flood coolant or oil will not work there. Heres a typical example. They are used for deep slotting or heavy side cuts and require less power than conventional end mills.

Hot sale good quality CNC Milling Tools D12x100. Regal Cutting Tools manufactures a variety of roughers for a wide range of materials and conditions. Influence of End Mill Helix Angle on Surface Quality of Aluminium Thin-Walled Parts.

3Straight Shank roughing Milling Cutter with 4 Flute. If so maybe Plunge Milling also called Plunge Roughing is the answer. Their extreme hardness means they are brittle so a highly rigid setup such as a CNC machine is necessary to prevent the end mill from.

Ideal for machining high alloyed steels titanium alloys and cast alloys.

Roughing Chip Breaker Bits 4 Flute F4zc45 End Mills Drills Frezycnc Eu

Lfc Widia End Mills 4s0r 4s4r Series

Geometrical Parameters Of An Endmill Download Scientific Diagram

Roughing End Mills रफ ग ए ड म ल In Bhosari Pune Orient Tools Id 3666888530

End Mill An Overview Sciencedirect Topics

Basic End Mills Technical Information Msc Industrial Supply Co

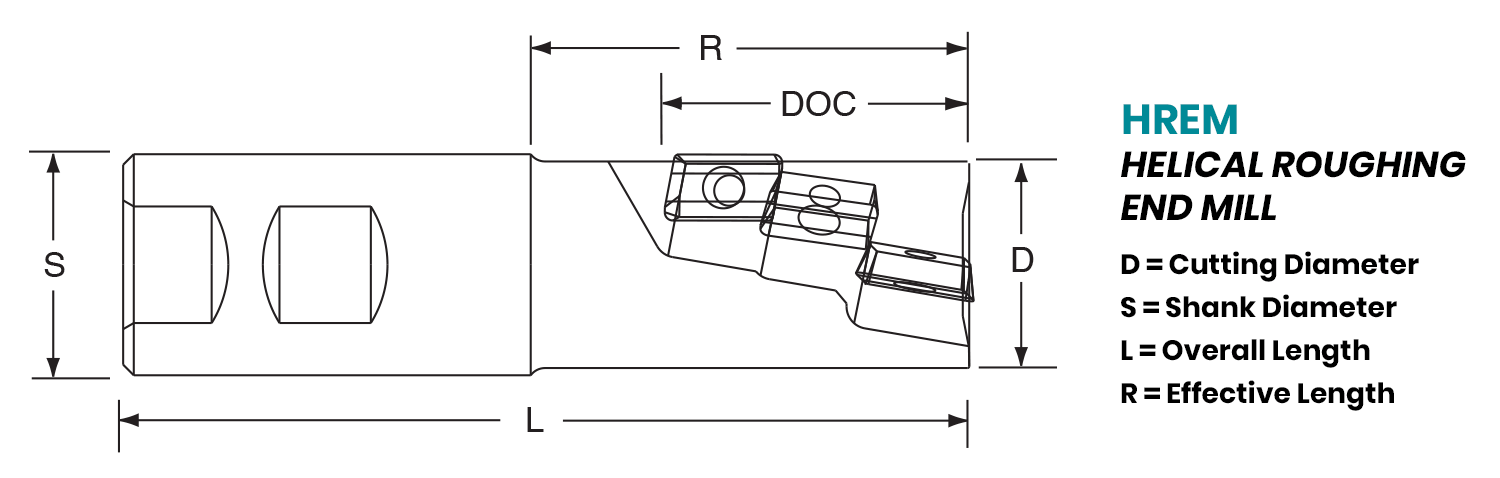

Helical Roughing End Mills Hrem For 10mm Apet Xpet Inserts Page 1

4 Flute End Mills For Hardened Steel End Mills Drills Frezycnc Eu